Exactly how to Pick the Best Welding Shirts for Heavy-Duty Work Environments

Exactly how to Pick the Best Welding Shirts for Heavy-Duty Work Environments

Blog Article

Discovering the Different Styles and Products Utilized in Welding Shirts to Improve Comfort and Security During Welding Tasks

The selection of welding tee shirts plays an essential function in stabilizing comfort and safety and security for welders in diverse settings. As we take a look at the specific styles and products offered, it becomes important to consider just how these options can eventually affect not just comfort, but likewise safety on the work.

Value of Welding Shirts

Welding t-shirts play an essential role in ensuring the safety and security and comfort of specialists in the welding market. These specialized garments are created to protect welders from the numerous dangers related to their job environment. High temperature levels, stimulates, and molten metal prevail dangers that can cause extreme injuries if correct protective clothing is not used.

Along with physical security, welding t-shirts are crafted from products that use flame resistance, which is crucial for protecting welders against prospective burns. The selection of fabric substantially impacts the t-shirt's longevity and performance, with materials such as cotton, jeans, and specialized artificial fibers being preferred options.

Furthermore, welding tee shirts are made to give comfort during long hours of labor. Functions such as moisture-wicking properties and breathable fabrics assist take care of sweat and temperature level, allowing for enhanced focus and performance. The ergonomic style and fit of these t shirts allow convenience of activity, ensuring that welders can do their jobs without constraint.

Popular Designs of Welding Shirts

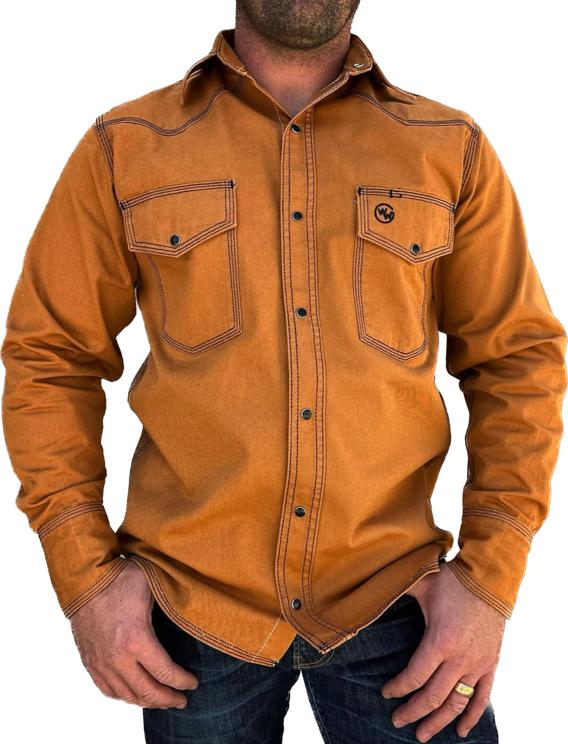

Different designs of welding tee shirts deal with the varied requirements of specialists in the market, each offering one-of-a-kind features that improve functionality and convenience. One prominent design is the long-sleeve welding t shirt, created to provide optimal protection and protect the arms from triggers and warm. These shirts often include reinforced sewing to endure the roughness of welding tasks.

An additional typical style is the short-sleeve welding tee shirt, which offers breathability and convenience in warmer atmospheres while still sticking to security standards. Some specialists choose button-up welding t-shirts, as they permit simple adjustments in temperature level and can be coupled with safety gear.

In addition, lots of welding t-shirts feature high-visibility styles, commonly incorporating intense shades or reflective strips to guarantee that welders remain noticeable in dimly lit conditions. This is specifically essential in commercial settings where safety and security is extremely important.

Lastly, welding t shirts with pockets and tool loops are increasingly preferred, offering welders with convenient storage space for vital devices and individual items. These designs combine security and practicality, making them crucial for experts in the welding sector.

Trick Materials for Convenience

Cotton is a prominent option because of its gentleness and breathability. It enables appropriate air flow, decreasing sweat build-up during intense tasks. 100% cotton might not be the ideal alternative for severe problems, as it can maintain warm and wetness.

Synthetic blends, such as polyester and nylon, are increasingly favored for their moisture-wicking abilities. These materials pull sweat far from the skin, keeping the wearer dry and comfortable (Best Welding Shirts). Additionally, artificial textiles usually have actually boosted longevity, withstanding deterioration from the rigors of welding tasks

Some producers are now including ingenious materials like spandex for included stretch, permitting improved mobility. This adaptability is crucial for welders, that require to navigate limited areas and carry out elaborate motions.

Eventually, the ideal mix of products can dramatically enhance comfort, making it essential for welders to consider their certain needs when selecting a welding t-shirt.

Flame-Resistant Attributes

Choosing the ideal welding shirt not only includes considering comfort and breathability however additionally ensuring appropriate defense versus potential risks, specifically fires and sparks. Flame-resistant (FR) features are crucial for Our site maintaining security in welding settings, where direct exposure to high temperatures and molten metal can present substantial risks.

Welding shirts created with flame-resistant products are typically made from specialized fabrics that have been dealt with or naturally have homes to withstand ignition and lessen melt injury. Usual products consist of cotton blends with FR surfaces, Nomex, and Kevlar, which supply efficient barriers against flames and thermal risks. These materials typically undertake strenuous screening to fulfill sector criteria, such as ASTM F1506 or NFPA 701, guaranteeing they supply reliable protection.

In addition to product selection, the design of the welding shirt plays an essential role in its flame-resistant abilities. Functions such as strengthened seams, high collars, and flame-resistant buttons or zippers contribute to overall security from this source by minimizing the threat of stimulates going into the garment. Investing in a welding shirt with durable flame-resistant attributes is essential for guarding the user against the inherent threats of welding jobs, making certain both convenience and protection on duty.

Tips for Selecting the Right Shirt

Taking into consideration the distinct demands of welding jobs, selecting the ideal welding shirt needs careful interest to several crucial factors. Focus on materials that offer flame resistance, such as cotton, dealt with cotton, or synthetic blends particularly made for welding settings. Ensure that the tee shirt meets suitable safety and security standards, such as those set by the American National Requirement Institute (ANSI) or the National Fire Protection Association (NFPA)

Fit is one more vital facet; choose a shirt that permits flexibility of motion without being extremely loose, as loosened fabric can catch on equipment or stir up. Furthermore, go with lengthy sleeves to protect the arms from sparks and heat (Best Welding Shirts). Search for functions such as strengthened stitching and long lasting joints, which improve the tee shirt's long life and hold up against the roughness of the work

In addition, take into consideration the environment in which you'll be functioning. T shirts with moisture-wicking homes can assist control body temperature and keep you comfortable during lengthy hours. Last but not least, evaluate the t shirt's breathability and weight to guarantee it stabilizes defense with convenience, enabling continual performance throughout your welding jobs.

Conclusion

In summary, the selection of proper welding t shirts plays an important duty in ensuring both comfort and safety and security during welding tasks. Different styles, including long-sleeve and short-sleeve alternatives, accommodate varied atmospheres while vital materials such he has a good point as breathable textiles and flame-resistant products give necessary security. Integrating attributes like strengthened joints and ergonomic styles additionally improves flexibility. Eventually, making educated options relating to welding t-shirts substantially adds to a much safer and much more reliable welding experience.

Report this page